There are a limitless number of uses for metal identification within the construction industry.

Proper identification provides resources for information, helps maintain safety standards, and aids in equipment monitoring.

Custom Metal Identification

Identification/Information

The main purpose for nameplates in a construction environment is identification.

They may be placed on machinery to indicate tolerances or provide manufacturer info in case of malfunction. There may be tags on tools so they don’t “mysteriously” go missing. There are a million different uses for tags on a job site.

Safety/Warnings

The most important part of any construction site is maintaining safety. This not only includes protecting construction workers but the general public as well.

Plus, adding safety nameplates is not always optional. There are numerous OSHA guidelines which require proper identification. That’s double the incentive to make sure all procedures are being correctly administered.

If a warning sign is able to prevent an accident or injury from happening, the return on investment is incalculable.

Asset Tracking

Organizations looking to keep tabs on their expensive machinery and equipment often turn to metal tags for asset tracking. By using either numbering or barcode scanning systems, monitoring assets becomes a breeze. With just a quick scan, pertinent information can be read about the piece of equipment or machinery.

Durability

Anyone who has worked in construction knows they are anything but clean and gentle. They’re typically outdoors, don’t stop for weather, and feature a fair share of dust and debris.

Tags could never hold up to those conditions right? Wrong.

Metal nameplates are incredibly durable and made to stay strong even in the toughest environments. For example, aluminum photo anodized tags are rated for 20+ year outdoor durability. This includes rain, snow, and just about anything your construction site can throw at it.

Other options include stamped metal tags as well as embossed metal tags.

That being said, not all tags are created equally. Durability ranges quite a bit depending on the material and process you select. For example: a screen printed tag is not going to last as long as an embossed tag.

Examples of applications

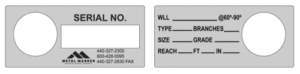

Sling Tags

A great example of how identification tags benefit construction site is sling tags. Construction crews across the nation use cable and rope slings for lifting heavy loads.

While they are an indispensable tool, improper use is incredibly dangerous. OSHA guidelines mandate the use of ID tags on every single sling. These tags indicate the type of hitch which should be used, load tolerances and restrictions, proper lifting use, and more.

Just by affixing a tag to the sling, workers and bystanders are safer, better educated, and also more effective.

Embossed Tags

Embossed tags are used for a wide range of applications in the construction environment. This can be as simple as tagging valves and pipes, or maintaining accountability for tools and parts. Metal embossed tags are incredibly durable, making them perfectly suited for the rigors of the construction workplace.

Metal buildings and bridges often use embossed tags to serialize beams. This makes the building process easier, faster, and all-around more efficient. They can even be applied before any coatings so there is no need to install or remove on-site.

MetalPhoto

Photo anodized aluminum tags are one of the most popular choices for construction sites due to their versatility as well as durability.

They can feature any design, image, logo, or text. This makes MetalPhoto a perfect solution for providing warning signs with information.

Photo anodized nameplates are also made to hold up in all environments. The design is actually embedded within the aluminum layers. This means it won’t be worn away in weather or work conditions.

In addition, the text can’t be easily scratched off like ink-based printing.

MetalPhoto is often used for nameplates on heavy equipment or machinery as it will last for 20+ years outdoors.

Wrap-Up

Proper identification is absolutely vital for the construction industry. Maintaining safety is key. Not only does it keep everyone on the job site safe, but reduces risk to bystanders and property.

Highly durable metal identification withstands the toughness of construction work, while providing important information and maintaining safety.

Ensure your next construction project is safe with custom metal ID solutions.