Aerospace nameplates are a vital (but often overlooked) part of the aerospace industry.

The last thing that may come to mind when thinking about aerospace is metal nameplates. Yet these markers are crucial to the success of aerospace organizations. Aerospace nameplates provide concise communication of important information.

Heavy regulations and strict specifications mean partnering with the right manufacturer is critical. At Metal Marker, we have handled many of these regulations and specs, and are well suited to handle your requests. We strive to work with you to meet or exceed most industry standards.

In addition, our quality management system is AS9100 certified.

Our customer service representatives are experienced in finding the perfect solution for aerospace organizations. Provide us exactly what you need your aerospace nameplates to be, and we will help guide you in the right direction.

Fill out our Free Quote form or give us a call at (800) 428-0095 today to get started.

Applications

Custom metal nameplates have an incredibly wide range of uses for this industry.

Asset tracking using barcodes provides an easy way for aerospace organizations to better manage their equipment and improve efficiencies.

Equipment and other machinery are often affixed with nameplates that indicate proper usage, safety warnings, manufacturer information, and more.

Safety signs and warning labels are often added to foster the safest environment possible.

Aircraft also need to be marked, as well as many of the parts that make up the finished product.

There are so many specialized parts and niches in this industry, which provides a great opportunity for identification solutions to ease some of the confusion.

Identification

There is very little margin for error when manufacturing, inspecting and operating aerospace equipment. From aircraft to machinery, one mistake can cost millions of dollars.

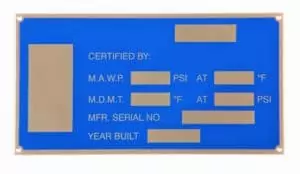

One of the most effective ways to prevent errors is prominent and accurate identification. Aerospace nameplates provide vital information to the people who rely on it most.

This can include identifying parts by serial codes, technical specifications, manufacturer information, and even safety guidelines.

By keeping your parts and equipment properly labeled with aerospace nameplates, your organization will be more likely to pass inspections, catch issues before they occur, and prevent accidents and errors.

Asset Tracking

Equipment and parts used in the aerospace industry are sometimes incredibly expensive. Tracking these vital assets using a code scanning system is one way to ensure they are being properly managed.

Asset traceability can be applied to nearly any aerospace part using our barcode nameplates.

Some of the most commonly used code types used include:

- Barcodes

- QR Codes

- Data Matrix Codes

- And More

Durability

Durability is a driving factor in this industry. Parts, panels, and components are often exposed to harsh conditions. This includes high temperatures, chemicals, sunlight exposure, and other weather.

Selecting material and process which is able to withstand the conditions the nameplates will be exposed to is crucial for a successful solution.

Not sure what is right for you? We are happy to help guide you to the right solution for your needs.

Materials

Aluminum

Aluminum is typically the preferred metal substrate used for this sector. The most important factor is the lightweight characteristic of aluminum.

Extremely strict specifications and weight tolerances are placed on aircraft, including military standards, flight safety, and more.

This makes aluminum a great solution as it doesn’t add significant weight to the components it is added to but provides outstanding durability.

Stainless Steel

If your nameplate isn’t going on a lightweight aircraft, or just needs to be as durable as possible, look no further than stainless steel. When the going gets tough, stainless steel steps in.

The material is sturdy and holds up to all conditions, including weather. Plus, wear and tear are not really a concern. The nameplates will be very long-lasting depending on the process you select.

Since it is a much heavier metal choice, stainless steel may not be the best option for all aerospace applications. It is also limited in process choices as MetalPhoto is not available.

For the utmost durability, stainless steel is a safe bet.

Processes

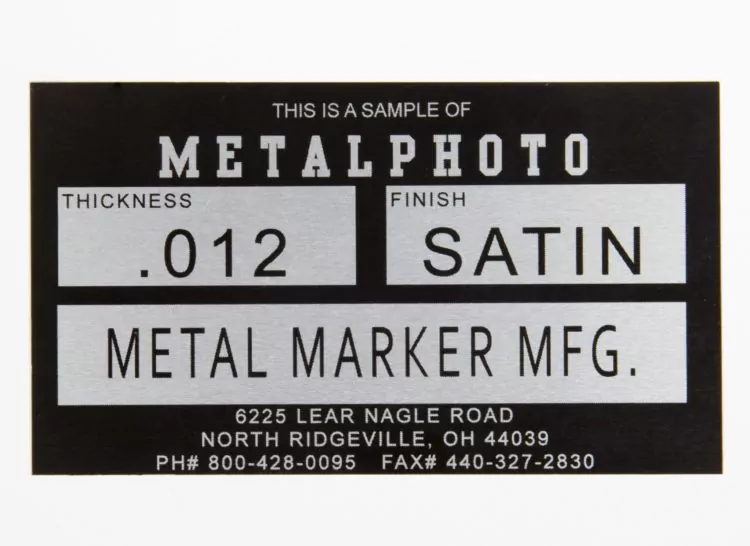

MetalPhoto

Photo anodization provides a high level of customization as well. This process allows for the addition of any image, design, text, numbers, barcodes, or even QR Codes. Want different designs on every nameplate? No problem! Add unique designs, or even serialized and/or variable data.

While it can’t do full-color designs like screen printing, it’s possible to add a solid color to the aluminum material.

Another great benefit to photo anodization is that there are many size and thickness options.

MetalPhoto sizes can go all the way up to 24″ x 40″.

With thicknesses ranging from .005″ to .125″, there is a right fit for every application.

The anodized aluminum material is also great for aerospace. Unlike screen-printed topical ink, the embedded design cannot be easily scratched off or otherwise removed. The aluminum is corrosion-resistant, durable, yet extremely lightweight. This makes it a perfect fit for the industry.

MetalPhoto nameplates are rated for 20+ years outdoors. This means they can hold up to all the wear and tear of industrial applications without losing their information or becoming illegible.

Embossing

For more simplified marking solutions, the embossing process provides a highly effective means to identify machinery, tools, and more.

These nameplates feature prominently raised characters created by a die set. This upward impression is extremely durable and suitable for aerospace applications.

In addition, serialized number embossed nameplates are perfect for making parts, tools, and more.

Stamping

This process uses a powerful stamp to press a design into the metal material. The indented text is remarkably long-lasting and easy to read.

These metal nameplates are desired due to their simple appearance and high durability. The stamped nameplate is not susceptible to scrapes or scratches and can hold up to tough aerospace environments.

Screen Printing

Screen printing is considered a versatile process due to its high level of customization. Since the tags are directly applied with ink, you can add almost any design onto the tag. This includes full-color logos, images, and more. This flexibility separates screen printing from other processes.

While the screen printing process offers great customization, it does have limitations as well. The downside is topical ink is prone to wear and tear. It will scratch off fairly easily. This is not considered a durable, long-term solution. It is especially true for tough industrial environments.

While it isn’t the most durable solution, it does have plenty of applications. For example, it can be great for indoor signage or warning markers that won’t see a lot of wear. Some organizations plan to replace their identification plates on an annual basis, in which case screen-printed tags might be a great choice.

Wrap-Up

With constant innovation and advancements, it is easy to forget all the small things that go into the world of aerospace. Custom metal nameplates provide highly important identification information to aid the manufacture and implementation of aerospace parts, products, and machinery. They also help provide pertinent safety info, show warnings, and make the industry that much safer.

The Metal Marker Advantage

We work with you closely to deliver high-quality tags that fulfill your expectations. And we’re honest when something is infeasible or impractical. We’ll propose an alternative solution that satisfies your requirements, budget, and timeline.