Employees in the electrical manufacturing industry work with a wide variety of materials and equipment, some of which can be hazardous. Electrical manufacturing companies are also responsible for ensuring their customers receive high-quality products and are aware of the potential hazards associated with their use.

Metal electrical tags are highly effective for communicating critical information to stakeholders, reducing the risk of injury and helping manufacturers build positive reputations. Keep reading to learn more about how these tags are used in the electrical manufacturing industry.

Communicating Safety Information

One of the most important uses of electrical tags is the communication of critical safety information to anyone involved in manufacturing, distributing or using electrical equipment. Working with electrical components can be dangerous, especially when stakeholders aren’t aware of the potential risks. According to the Occupational Safety and Health Administration, cable harnesses, overhead lines, circuits and other electrical system components can cause shock and electrocution if they’re not handled correctly. These components can also cause fires that result in serious burns and property damage.

To produce electrical components, many manufacturers also use hazardous machinery and tools, making it even more important to communicate safety information to employees across the organization. Metal electrical tags are ideal for this purpose, as they’re much more durable than other types of identification materials. These tags can be attached to machinery or electrical components, ensuring everyone understands the potential hazards associated with using each item. Here are some examples:

- Circuit Switch Off

- Do Not Operate

- Electrical Hazard

- Passed Inspection

- High Voltage

- Do Not Touch

- Leak Detector

- Electrical Panel Locked Out

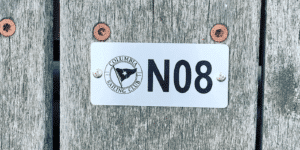

Tracking Inventory

Good inventory management is essential for increasing profitability, as it helps electrical manufacturers keep better track of their products, reducing the amount of money spent on replacing lost or mislabeled items. Many companies now use automated systems to track inventory at every stage of the production process and as it travels from the plant to wholesalers or retailers. Electrical tags are ideal for inventory tracking because they can be etched or printed with bar codes, making it easy to scan each item on the production floor, in the warehouse or upon arrival at its destination.

Electrical manufacturers also use metal tags to track tools and equipment, reducing the risk of theft and other forms of fraud. If theft does occur, inventory tags are helpful for determining when and where it took place, as they’re scanned at every point in the logistics flow. If an item goes missing after it leaves the warehouse and before it arrives at the wholesaler’s loading dock, for example, then it’s likely the theft occurred at some point during transport. Some companies even use metal tags to label furniture, forklifts, storage racks and other items, making it easier to track assets or learn more about how assets are used within an organization.

Identifying Equipment Status

To reduce downtime, employees need to be able to identify the status of a machine within a matter of seconds. Many companies use tags made of card stock for this type of communication, but card stock rips easily and may disintegrate if it’s exposed to water, machine oil and other substances. Metal electrical tags are much more durable, making them a better choice for companies that need to communicate the status of expensive equipment to employees. Tags can be used to indicate a machine is due for service, down for repairs or ready to use.

Documenting Operating Standards

Manufacturing equipment and electrical components are designed to be used under specific conditions. If employees or customers are unaware of those conditions, they may inadvertently use an electrical component or piece of equipment in an unsafe manner. Many companies document their operating standards in employee manuals, but employees on the production floor may not be able to access these manuals quickly. Additionally, some employees have to travel to other work sites, making it difficult to access information that’s hidden away in a binder.

To make everyone aware of important operating standards, electrical manufacturers are now using metal electrical tags to communicate information about temperature ranges, moisture levels and other conditions that can affect the safe operation of a piece of equipment. Manufacturers can also use electrical tags to let customers know if they need to take extra precautions when using electrical components for commercial or residential purposes.

Following Workplace Safety Rules

Electrical tags even make it easier for electrical manufacturing companies to adhere to state and federal workplace safety regulations. OSHA and other agencies set standards that most employers must follow, making companies responsible for protecting employees from a wide variety of hazards. For manufacturers, standards regarding energy control procedures are extremely important. According to OSHA’s energy control regulations, employers must give employees written instructions for eliminating the potential for unexpected machine activation or unexpected release of stored energy.

By using electrical tags, manufacturers can instruct employees on preparing for shutdown, shutting down equipment and machines, disconnecting energy-isolating devices and taking other steps to prevent serious accidents. Electrical tags are also useful for communicating the type of hazardous energy present and the magnitude of that energy.

Order Custom Electrical Tags

Adhesive labels are fine for envelopes and other non-critical items, but they’re not durable enough to use for tracking inventory, communicating important safety information or helping employees identify a machine’s status within a few seconds. Metal Marker Manufacturing produces custom electrical tags made from metal, giving electrical manufacturers a durable alternative to perishable labeling products.

These tags are marked with critical information, protecting employees from hazards and making it easier to track assets. To learn more about our electrical tags or place an order for custom tags, call us at (800) 428-0095.