Pipes are a fundamental element of many industrial type organizations. From energy companies to manufacturing plants, there are many different ways pipes are used.

Pipe tags and labels are used to accurately and durably mark and identify pipes for industrial organizations.

Process Options

Labels

As pipes are cylindrical by nature, a flat attachment is not always possible (depending on the diameter of the pipe). As such, many industries have turned to custom labels. These labels are affixed around the pipe using heavy duty adhesive.

Labels can be produced with full color designs, allowing for vibrant and easy to view identification, even in dimly lit environments.

Industrial pipe labels typically feature white or black text on a solid color background. Most of these labels are also adorned with arrows offering a clear indication which direction the pipe flows. This is especially useful when dealing with complex pipe systems that shift in multiple directions simultaneously.

Embossing

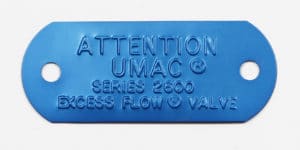

Embossed tags are produced using a die set, which creates a raised design. This type of marking is incredibly durable, and tough enough to handle exposure to water and other chemicals.

Since the design is raised, if the tag gets painted over or otherwise obscured, it will remain legible.

If the tags are produced from anodized aluminum, they can also be color coded for sorting purposes or to quickly identify the type of liquid flowing through the pipe.

Embossing is also a popular marking process for pipe valve tags, including steam traps.

Attaching an embossed tag to a rounded surface might sound like a daunting task. These nameplates can either be mounted to a nearby flat area, or attached via a wire which wraps around the diameter of the cylinder.

Photo Anodization

The photo anodization process differs from embossing as the design it produces is completely flat to the touch. This unique process embeds information in between layers of aluminum for maximum durability (20+ years outdoors).

Photo anodized pipe tags can be produced with any design, text, barcode, or logo. Color coding is possible as well since the material is an anodized aluminum.

Similarly to embossed pipe tags, these nameplates are often attached via wire. However, they can also be placed using an adhesive backing if the pipe is large enough and the aluminum is thin enough to bend around the contour of the pipe.

Industries

There are a wide range of industries which rely on identification tags for marking their pipes.

- Energy

- Oil & Gas

- Aerospace

- Construction

- And Many More

Regulations

ANSI/ASME guidelines specify marking pipes for safety purposes. These industry standards are laid out within ANSI/ASME A13.2-2015.

Labels for pipes are recommended to be produced to these specs to standardized safety practices across plants and facilities.

Examples: White text on a blue background is compressed air. Toxic & corrosive fluids is black text on an orange background.

In addition there are specific size guidelines based on the diameter of the pipe. For example: an 8-10” pipe requires a 24” colorway and characters that are 2 1/2”.

Valve Tags

In addition to marking and identifying pipes, many organizations also use tags on their pipe valve fixtures. They are used for inspections as well as for traceability.

Numbered tags are often used to quickly identify which pipe valves need serviced, and which are fully-functioning.

Similarly to pipe markers, valve tags are sometimes color coded based on the type of liquid in the pipe.

Materials

Some of the most commonly used materials include:

- Anodized Aluminum

- Poly/Vinyl (Labels)

- Stainless Steel

- Brass

Wrap Up

Proper identification in an industrial environment is crucial. Not only does it provide relevant information to workers, but it helps maintain a safe environment.

Labeling pipes with tags or labels provides a simple but effective way to communicate information.