Metal nameplates have utility across a wide range of industries, as well as making excellent custom labels for practically any brand. You might use engraved nameplates for warnings, customized merchandise and machine identification, among many other practical applications.

Stainless steel nameplates offer unparalleled durability when it comes to harsh environments over extended periods. Chemical resistance is one of the major highlights of this type of metal tag, so you can count on them for an array of indoor and outdoor uses.

Applications for Metal Nameplates

When it comes to durability, stainless steel is an excellent choice for a nameplate that needs to go the distance. While aluminum nameplates have the upper hand when it comes to colorization and weight, stainless steel metal labels are the most durable and unbreakable option. They can withstand chemicals, scratches and harsh weather — and if there’s a risk the tag might get bent, there’s no better choice than stainless steel.

The top applications for stainless steel tags include compliance, signage, barcodes, serial numbers and custom design merchandise.

Compliance

Stainless steel nameplates are some of the easiest to read because it’s possible to etch or stamp letters and numbers onto the surface. Unlike aluminum that needs to be anodized, ink processing doesn’t last as long on stainless steel. However, stamping and etching make permanent marks that workers and auditors will be able to read for decades.

Industries such as aerospace, medtech, mining and the military have stringent compliance rules and regulations. Metal nameplates can help decision makers deliver the most cost-effective solutions for labeling for compliance purposes, whether the equipment is indoors or outdoors.

Signage

It’s not just industries with high-level compliance requirements that benefit from stainless steel metal tags. Any facility that needs to display important information can make use of them.

For example, bathroom or navigation signage made from metal lasts longer than plastic or stenciled signs. Paint chips or scratches lower your brand’s value, while sturdy, attractive stainless steel signs project professionalism and quality.

Equipment Identification

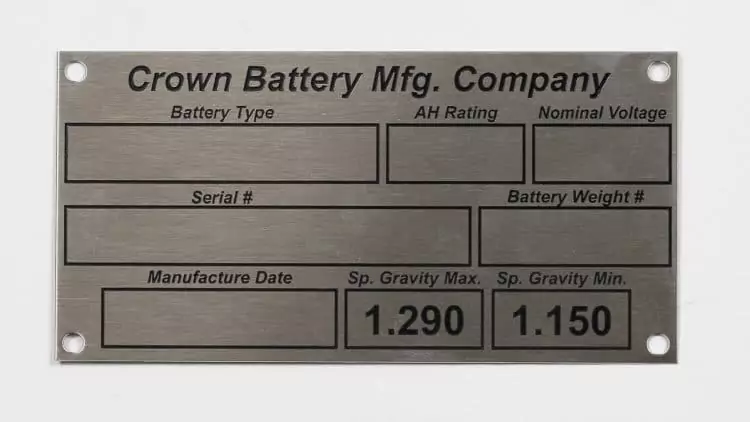

Small plates made from stainless steel can display manufacturer information on a machine or whatever information your warehouse or workshop needs to convey. When it comes to training new employees on how to use equipment, mini signs that indicate the order of use or simple information can save time and money during the onboarding process, as well as improving overall employee performance.

Product Labeling

Plastic nameplates are at the mercy of weather and the elements, while stainless steel is one of the most durable, high-quality metals out there. Wherever your products are stored, you can use metal tags to label them and streamline operations. It doesn’t matter if the labels need to stand up to abrasion, corrosion or any other potentially damaging environment, stainless steel is the most hard-wearing material for product labeling.

Brand Promotion

If you’re the owner of an SME, one of the best current marketing tactics is customization. You can send out customized metal nameplates to your best customers to encourage social media engagement — or offer them as a prize to competition winners who post the best-performing UGC.

If you’re currently getting your company off the ground, consider sending them out to prospective clients or vendors and give a branded nameplate out with each purchase. You can create decals, business cards, pet tags, door signs and more to get your brand’s logo noticed out there in the world.

Why Stainless Steel Nameplates?

You can get stainless steel tags in a variety of thicknesses, with a smooth or brushed finish, depending on your company’s needs. Stainless steel is a robust and hard-wearing substrate, which means you can use it in indoor and outdoor environments. We can clearly mark important information such as etched serial numbers, instructions and regulatory codes onto its surface — and the nameplates can last for decades.

The finish is sleek and attractive, but durability is the biggest advantage of this material. It’s particularly well-suited to military and industrial applications, where the finish of serial numbers and display models looks crisp and easy to read. Stainless steel offer resistance to:

- Water

- Heat

- Corrosion

- Abrasion

- Chemicals

- Solvents

Industries That Use Stainless Steel Tags

Metal tags, nameplates and labels have utility across many industries because they allow bosses to easily meet industry and company standards. Any vertical that uses heavy machinery, such as the military, gas and oil or transportation and aviation, can use metal nameplates to improve compliance and workflows. Safety signs, labeling and tracking are useful for practically any company, but some of the most popular industries for metal tags include:

- Hospitality

- Food processing

- Architecture

- Pump manufacturers

- Security hardware

- Construction equipment

- Furniture

- Logistics

- Medical

- Aviation

- Retail

- Health and safety

- Aerospace

Nameplate Customization

The state-of-the-art facilities here at Metal Marker mean we can perform an array of different processes and finishes depending on your company’s unique requirements. We can print your logo, message or designs onto practically any material, including stainless steel. Our cutting-edge printing and embossing techniques mean you can add appealing or practical finishing touches to metal tags.

Processes

Below is a list of the various processes we can use to finish your stainless steel nameplates.

Engraving

Engraving involves leaving deep indents in the stainless steel to add text, numbers or a design onto the surface. A lot of time and attention is necessary to get this process just right because each letter is added individually, but the finish is impeccable.

Stamping

A faster, cheaper method of adding data or images to a metal tag is by using a single stamp and embedding the whole design at once. The text or data is imprinted on the surface of the stainless steel tag, and while it’s not as deep as engraving, the finished product won’t wear off.

Embossing

While engraving and stamping embed a design onto the surface, embossing creates raised designs that can withstand galvanizing, painting, acid cleaning, sandblasting and severe weather. Characters are added one at a time, so you can add variable and serialized data using this process.

Related Blogs

Related Videos

The Metal Marker Advantage

We work with you closely to deliver high-quality tags that fulfill your expectations. And we’re honest when something is infeasible or impractical. We’ll propose an alternative solution that satisfies your requirements, budget, and timeline.