We produce high-quality custom valve tags to service a wide range of industries. Valve identification has never been easier with our custom industrial tags. Increase safety and prevent accidents from happening within your facilities.

We understand there are crucial components for organizational systems that use pipes and valves to regulate the flow of chemicals, liquids, etc. That’s why our valve tag material is long-lasting and made to withstand wear and tear in tough environments. Whether you need stainless steel, aluminum or brass, our valve tag pipe markers are perfect for the job.

Ready to get your custom valve tag order started, but still not sure where to begin?

Don’t overthink it — let us help.

Our highly knowledgeable customer service representatives have years of experience producing high-quality valve ID tags. We can provide you with key insights and the best solutions. We will help you find the perfect customized valve tag solution for your application and are prepared to handle all questions and concerns until you’re satisfied.

Contact us today for a FREE quote on your custom valve tags and pipe markers!

Fill out our easy contact form on this page or give us a call at 1-800-428-0095.

Overview

Custom valve tags are essential for efficient and safe operations in industrial and commercial facilities. These tags clearly identify valves, ensuring quick and accurate access during maintenance, repairs or emergencies.

Benefits

You can use these tags to organize complex piping systems or display critical safety information. They help streamline processes and reduce the risk of costly mistakes. By choosing custom metal valve tags, you benefit from superior durability and tailored designs that meet your specific operational needs.

Applications

What Are Common Applications for Valve Tags?

An important goal for all workplaces is to ensure a safe environment for their employees. Industries that use valves know far too well how easily an injury can occur due to a mistake or improper labeling. If correct safety protocols are not followed, valves can be hazardous.

This is where valve ID tags come in. They provide proper labeling and identification of pipes and valves. By properly identifying what the valve or pipe contains, anyone who comes into contact with it will be safer. They will understand the risks involved and follow the correct precautions to stay safe.

Mistakes happen, but they are preventable. Utilizing custom nameplates for valves will make your organization much safer.

Identification Tags

Clear and prominent identifying information is very important in industrial environments. It can be easy to get two valves mixed up, causing errors or slowing down processes. Being able to identify all relevant information to ensure correct procedures are followed is a very powerful tool for any business.

Valve Inspection Tags

Valve inspections are an essential part of the industrial business. Making sure they are functional and up to safety standards is a must.

While these inspections can take a long time, valve and inspection tags for equipment make them much less of a headache. Clear labeling means quicker, easier and more accurate inspections that save you valuable time.

Safety Valve Tags

Safety is always a top priority. If employees are not cautious when working with valves and pipes, they may be exposed to potential hazards. One mistake is an accident waiting to happen.

Safety valve tags eliminate any guesswork and keep employees safe. Write-on tags can even be used to mark when equipment is broken or needs to be repaired.

There are also numerous OSHA and ANSI guidelines that require safety signs in potentially hazardous environments. Don’t let your facility fall behind on OSHA or ANSI standards. Keep your staff safe with long-lasting safety solutions.

Safety Release Valve Tags

Safety release valve tags provide an effective method for marking and identifying crucial valve systems.

When pipes become overpressurized, they pose an immense hazard to employees and equipment. One ruptured pipe can cause an entire emergency.

Organizations combat this risk by incorporating safety reliefs into their valve systems. These releases offer a quick and efficient way to limit the amount of pressure and reduce the potential for an accident to occur.

Labeling relief valves with metal safety placards helps distinguish them from other systems, prepares them for inspection and ensures they meet safety regulations.

What Is a Safety Relief Valve?

A pressure release valve is a safety regulator that limits the amount of pressure in a system.

Also referred to as pressure relief, these valves are pre-set to release before a system exceeds its pressure limitations.

Fluid or gas (or a combination of both) is directed out of the system using an opened auxiliary passage. The pressurized substance flows through this pathway as it offers the least resistance.

As the fluid is rerouted, it is typically led into a combustion area to be burned and released into the open air. This effectively eliminates the excess and quickly reduces the system’s pressure.

Overpressurized Pipe Risks

If your pipe system does not include a safety relief system, pressure can exceed safe limits and pose a massive safety risk.

Overpressurized pipes can rupture, leading to leaked gas or fluid. This can cause massive damage to equipment and put employees at severe risk of injury. If not sufficiently contained, leaked gases and chemicals can even become a public safety hazard.

Bypass Valves

In addition to relief valves, other valves are used for various systems. Bypass valves are sometimes used in lieu of a release valve. These safety regulators work very similarly. However, instead of allowing fluid out of a system, they deliver excess fluid to a reservoir.

This not only relieves the pipe but also prevents the pump from being over-pressurized. Fire engines are one of the most prevalent uses for bypass valves.

Safety Valve Regulations

Keeping up with all pertinent safety requirements is vital for every industrial organization. Anything less than up to code can lead to equipment malfunctions, workers’ danger and hefty fines.

Having safety relief valves in place is a great step in the right direction. They provide an effective mechanical means to prevent issues. In order for them to be properly used and maintained, they must also be clearly identified with metal identification tags.

Clear identification ensures they are not tampered with or mixed up with a normal valve.

Industries

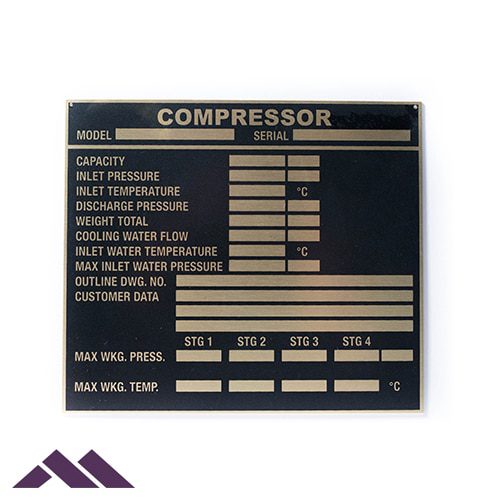

Custom metal data plates are used by a wide range of industries. From shipyards to manufacturing plants, most industrial organizations rely on identification plates.

Manufacturers affix plates to their equipment to provide accurate specs and information to operators. Construction machinery such as forklifts is marked with weight tolerances and guidelines. Shipping containers are marked with mandated info for international commerce. The list goes on and on.

Some industry examples include:

- Construction

- Energy

- Equipment Manufacturers

- Government (Federal, State and Local)

- Oil & Gas

- Telecommunications

Materials

Anodized Aluminum Valve Tags

Anodized Aluminum Valve Tags

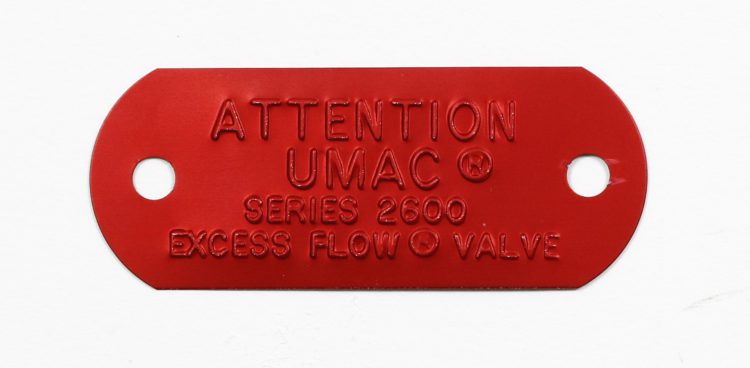

Anodized aluminum, one of the most popular materials for valve identification tags, is highly versatile. It is an incredibly durable substrate used in everything from aerospace equipment to manufacturing facilities.

Anodized tags are made to hold up to the rigors of industrial use. They are resistant to wear, weathering and corrosion.

The anodization process also allows for a solid color to be added to the metal plate. This provides the opportunity to color code various valve types or just create a more stand-out warning sign.

Stainless Steel Valve Tags

Stainless steel, another widely used metal in this field, sets the standard for durability. The material is incredibly sturdy and resistant to just about anything it may be exposed to in an industrial-type environment.

Coupled with a durable stainless steel marking process, these release valve markers will last for many years.

Durability

When durability matters most, metal valve tags offer unmatched performance. Made from durable materials like stainless steel, brass and anodized aluminum, they resist corrosion, high temperatures and abrasive conditions, making them ideal for high-stress applications.

Custom valve tags maintain their clarity and legibility over time, even after being exposed to outdoor weather, chemicals or heavy handling. At Metal Marker, we offer options like laser engraving and protective coatings, ensuring tags remain reliable even in the harshest conditions.

Processes

What Processes Are Available for Valve Tags?

Custom Stamping and Embossing

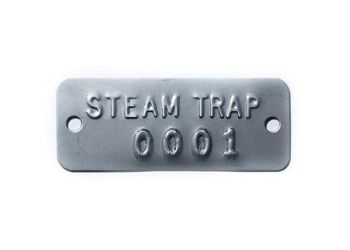

Custom stamping and embossing are two of the most widely used processes for marking tags. These processes mark valves of all varieties.

One of the most popular choices for valve identification tags is the metal embossing process. A die set punches the metal, creating a raised design, making it incredibly durable and perfect for industrial environments. Steam trap labels are often embossed to make them easier to read in any condition.

Both embossing and stamping press a design directly into the metal substrate. Embossing raises the information, while stamping creates indented or recessed characters.

Some organizations choose to mark their own blank tags on-site with an embossing machine or label printer.

Photo Anodization

Photo anodization is a unique process that embeds information in between layers of aluminum material. This provides the appearance of printed text but with outstanding durability. These tags are resistant to scratches, chemicals, weather and more and are estimated to last for 20+ years outdoors. These metal labels are much more durable than plastic valve tags or temporary paper tags.

Write on Valve ID Tags

If you need to add more information on-site, we provide write-on ID tags that allow you to do so.

Custom Etching

If you need your nameplate information to feature color, the etching process is a solid choice. After the design is imprinted using a chemical or laser etching process, the characters are filled with a color of your choosing.

While this provides a stand-out appearance, keep in mind that etching is not the most durable marking process. The color infill will quickly wear if exposed to tough conditions. While the etched metal itself will last longer, it is still susceptible to wear as the impression is not very deep in the material.

Custom

At Metal Marker, our identification products are truly custom solutions. Our industrial label makers can create valve tags or placards of any size, shape or design. Add any text, barcode, number system, logos, etc. If you want custom identification products, we can make it happen.

Add color to aluminum valve tags with anodized aluminum. Their vibrant designs make it easier to identify your pipes in low lighting or from a distance. They are also frequently used for color-coding pipes.

Attachment Methods for Valves

In addition to choosing the best process and material for your application, it is equally important to decide how to attach your valve identification tags.

Beaded chain

For fire extinguishers and other safety labels requiring valves, a beaded chain looped through the tag is a popular choice. Tag fasteners and other hardware are great options for equipment repair tags or machinery near valves.

Adhesive for Pipe Markers

Adhesive backing or banding tape may be used when attaching custom pipe markers to avoid damaging the pipe.

Note that the marking process selected may impact the attachment method options. For example, stamped brass valve tags cannot utilize adhesive backing due to the nature of the process.

Wrap-Up

Why Metal Marker Is the Right Choice for Your Valve Tags

At Metal Marker Manufacturing, we specialize in producing custom metal valve tags designed to last. With overnearly a century of expertise, we deliver high-quality solutions tailored to your needs, ensuring every tag meets your specifications.

Our team combines cutting-edge technology with exceptional customer service to provide you with valve tags that enhance the safety and efficiency of your operations. Whether you’re outfitting a new facility or upgrading your current system, we are here to help.

Ready to get started? Call us at (800) 428-0095 or fill out our contact form to order your custom valve tags today.

The Metal Marker Advantage

We work with you closely to deliver high-quality tags that fulfill your expectations. And we’re honest when something is infeasible or impractical. We’ll propose an alternative solution that satisfies your requirements, budget, and timeline.